A purple haze, sparked from a jolt of electricity, is the fourth state of matter known as plasma. And once fit to purpose, plasma can do almost anything:

Kill deadly pathogens on fruits and vegetables. Make fertilizer from thin air. Supercharge water into a powerful sanitizer. Convert liquids into solids - or into rarer, valuable oils.

But Dr. Kevin Keener, a University of Guelph engineering professor who first imagined the technology known as high-voltage atmospheric cold plasma, almost three decades ago, is driven by its life-saving potential:

"There are over five million children in Africa impacted by mycotoxins in food," says Keener, referring to the poisonous compounds produced by moulds that flourish in high-humidity environments.

"Our gas chemistry destroys these mycotoxins."

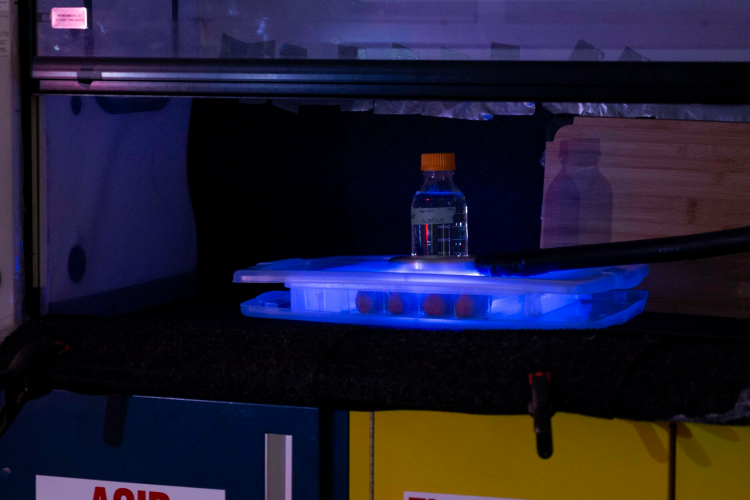

Cold plasma, glowing matter seen also in a plasma globe, can kill deadly pathogens in foods

Awarded the inaugural Barrett Chair in Sustainable Food Engineering for this research, Keener adds:

"We can treat food; we can improve safety, sustainability and reduce energy costs, sure. But these things that are directly impacting human health that, to me, is my biggest priority."

Cold plasma's near endless global applications

Over 25 years ago, the idea began with just two pieces of cardboard.

Working with industrial engineers using plasma jets to treat glass and circuit boards, Keener was the first to see clear applications in the food processing industry. At the time, plasma wasn't effective enough for food safety; Keener set out to change that.

His first prototype used coils of speaker wire wrapped around thin pieces of cardboard, which he connected to a simple transformer. He showed that when an electric field passes through a sealed environment, like a food package, the air inside fizzes into a cool glow, a plasma, which makes short-lived molecules that can destroy pathogens in moments. The package remains closed the entire time. Food quality remains intact.

That setup alone addresses major problems with food sanitization. Chemicals can leave behind residues, and re-opening a package can re-contaminate what you just cleaned. A chemical-free, sealed-pack treatment promises longer shelf lives and fewer losses.

Those principles have remained the same in his U of G lab today. But more sophisticated high-voltage supplies have made the technology more adaptable.

When an electric field passes through a sealed environment, the air inside fizzes into cold plasma, making short-lived molecules that can destroy pathogens in moments

Food safety is, therefore, just the beginning. Clean Crop Technologies, which Keener co-founded in 2019, uses his patented technology on seeds, grains, nuts and more. Plasma cleans the seeds and sparks stronger water uptake, doubling their germination rates, which could double the world's crop outputs and our food supplies.

Cold plasma technology also changes the structure of common compounds, a modern-day alchemy. Able to manipulate the bonds within lipids, the plasma can turn simple oils into "preferred" oils, like palm oil. This has economic and political value, as making palm oil in Canada could reduce reliance on other countries.

And so, Keener imagines a world where his tech is as common as a flashlight.

"It can be built portable," he says. "Imagine you're a hiker sterilizing water in the mountains or eliminating insects in your food. Or if you're a doctor, we've shown that it can attack certain kinds of skin cancer. The potential is endless."

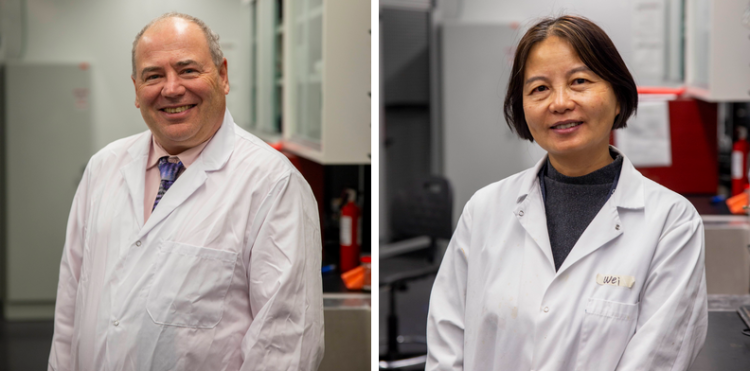

Dr. Kevin Keener (left) and researcher Dr. Wei Cao

Plasma-activated water kills salmonella in minutes

One of the biggest challenges of cold plasma is the constant need for iteration. Variables such as electricity supply need to be fine-tuned for every purpose. But the learning experiences can be well worth it, as Himashree Ponrajan came to know firsthand.

Ponrajan left her home in India in 2022 to pursue a research-based master's in Keener's lab, drawn to U of G's reputation in food and agriculture and a chance to work on the renowned technology.

She knew ordinary tap water can be charged with plasma to make plasma-activated water, which can wash toxins off the surfaces of peanuts, fruits, even medical scalpels. Her project focused on developing plasma-activated water to eliminate salmonella on chicken while preserving the quality of food.

"We wanted to build something that could be scaled up and used in industry," she says, which is why the lab opted for a minimal set-up: plastic boxes, accessible transformers and room temperature requirements only.

Two years of engineering later - tinkering with the transformers, the size of the box, the gaps between electrodes and countless other variables - Ponrajan was proud to publish results: 99% of salmonella removed in under 10 minutes of cold plasma treatment.

"We've gotten interest from researchers who are building proposals from our results," she says. "It makes me feel we've achieved something on the cutting edge."

North America behind on cold plasma

Decades since cold plasma was first imagined, researchers are ready for its next chapter: convincing others to buy in.

"The first challenge is prototypes," Keener says. "Companies want a machine they can see on their products."

On a recent trip, Dr. Wei Cao, research scientist in Keener's lab, toured several sites across China, discovering dozens of such specialized prototypes.

Though China is not specializing in cold plasma's food safety applications, she says, North America is still behind, dealing with a lack of prototype funding and no steady supply chain that can manufacture the technology's complex equipment. That would take a whole cultural change and mindset shift on the part of governments and industry.

But Keener remains optimistic that cold plasma will one day see the light it deserves.

"This is a technology that can transform lives, practically and meaningfully," he says. "People are dying from a lack of this technology. So, to me, success is beyond commercialization. It's about making cold plasma a common, widely available solution that can solve challenges in food safety, agriculture and human health."

He adds: "We're focused on perfecting it. And we are learning more and more every day."